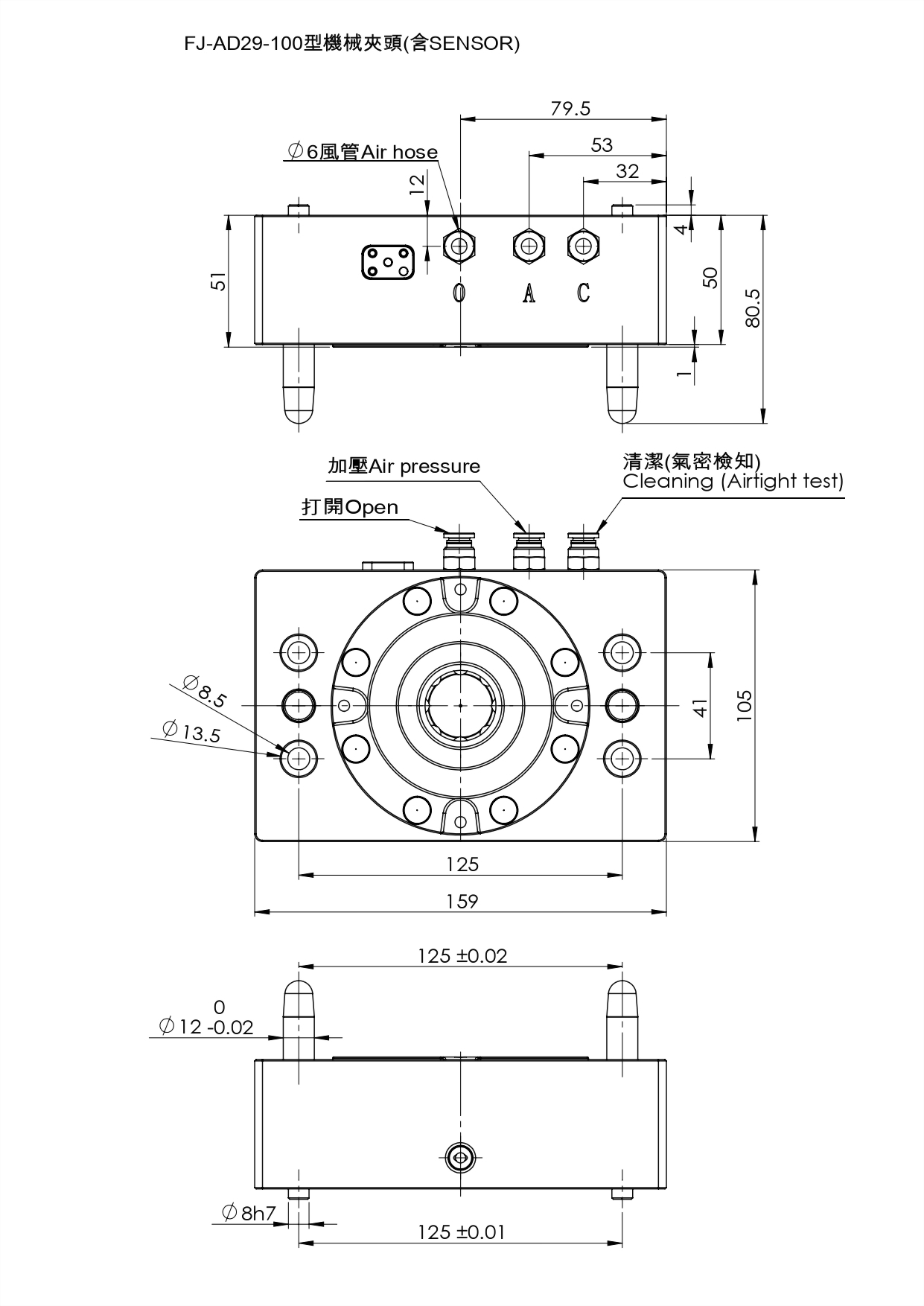

2.Weight: 3 kilograms.

3.Pneumatic control, with an air supply requirement of 6 bar.

4.Maximum load capacity: 100 kilograms.

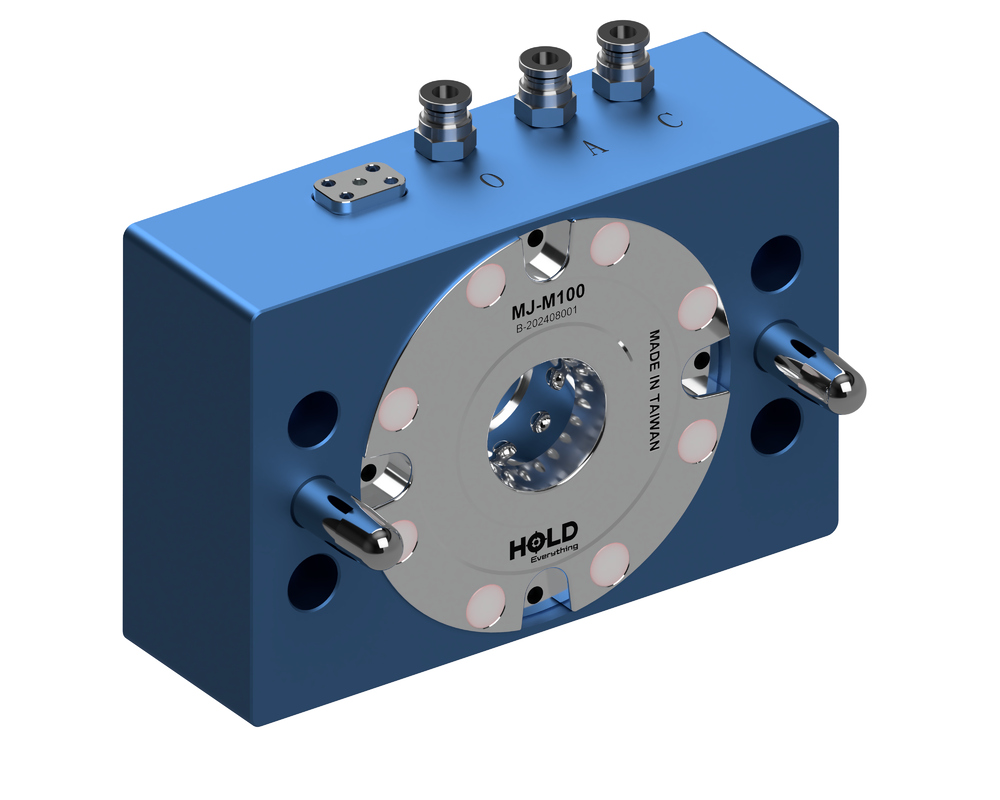

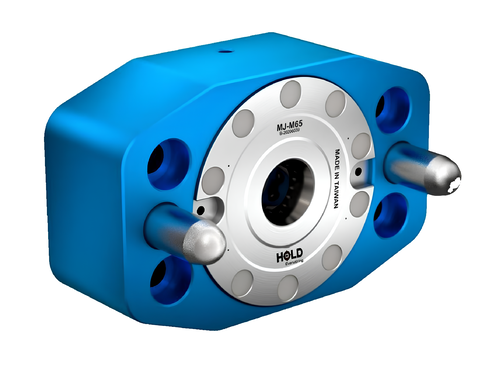

Simple structure: The clamping and supporting surface is made of HRC57 stainless steel, ensuring durability and the ability to withstand higher loads.

Built-in sensor: Capable of detecting whether the object is being gripped or released.

Drive method: Pneumatic, with a minimum air supply pressure of 6 bar.

Wide application: Primarily used in automated production, effectively improving production efficiency.

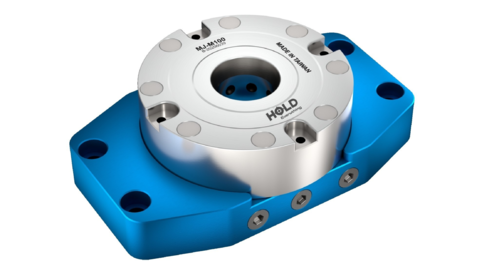

Dimensions:Gripper diameter100mm

Drive method:

· Pneumatic: Operating pressure 6 bar.

Sensor function:

· Sensing distance: 1.5mm

· Maximum detection distance: 2.5mm. Stable detection even in vibrating operating environments.

· Low current consumption.

High-precision gripping:The built-in sensor detects whether the object is being gripped or released, ensuring precise gripping.

Flexible adaptation: Capable of gripping trays, with the ability to handle objects of various shapes and sizes on top of the trays.

Durable materials:The clamping and supporting surface is made of HRC57 stainless steel, ensuring durability and the ability to withstand higher loads.

Automated control: Pneumatic operation enhances operational efficiency.

Versatile: Widely used in automated production lines, material handling, and other fields.

Easy installation and maintenance:Simple to install and maintain.

Robotic arm application in production: Works in conjunction with robotic arms for precise operations, enhancing efficiency.